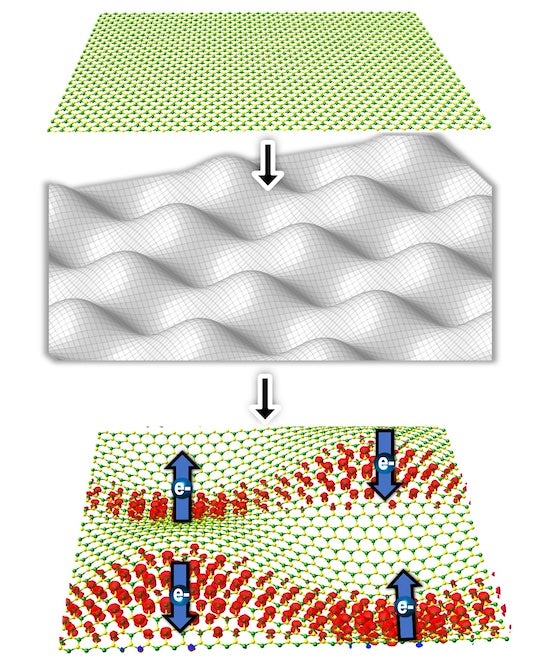

Representation of electron spins in a bent 2D material exhibiting the persistent spin helix structure. (Image courtesy of Sunny Gupta)

Wrinkles can be an asset — especially for next-generation electronics. Rice University scientists have discovered that tiny creases in two-dimensional materials can control electrons’ spin with record precision, opening the path to ultracompact, energy-efficient electronic devices.

If most devices today use the charge of electrons flowing through silicon to process and encode information, future computing may instead harness spin — a quantum property of electrons that takes on either an “up” or “down” value. Computing with spin could overcome the limitations of current silicon-based technology, reducing the energy footprint of devices and data centers at a moment when computing-driven energy use is soaring globally.

However, spintronics has to contend with a major challenge: Information encoded in spin is quick to decay and can be lost when the electrons in a material scatter and collide with atoms.

In a new study published in the journal Matter, Rice materials scientists have reported that bending atomically thin layers of materials like molybdenum ditelluride, MoTe2, gives rise to a unique spin texture called persistent spin helix, or PSH, which can preserve spin state even in scattering collisions.

– See more at Rice News

contoured substrates

contoured substrates

It’s now possible to quickly make ultrathin nanoribbons of

It’s now possible to quickly make ultrathin nanoribbons of  Scientific studies describing the most basic processes often have the greatest impact in the long run. A new work by Rice University engineers could be one such, and it’s a gas, gas, gas for nanomaterials.

Scientific studies describing the most basic processes often have the greatest impact in the long run. A new work by Rice University engineers could be one such, and it’s a gas, gas, gas for nanomaterials. Carbon nanotube fibers are not nearly as strong as the nanotubes they contain, but Rice University researchers are working to close the gap.

Carbon nanotube fibers are not nearly as strong as the nanotubes they contain, but Rice University researchers are working to close the gap. Mixing and matching computational models of 2D materials led scientists at Rice University to the realization that

Mixing and matching computational models of 2D materials led scientists at Rice University to the realization that  One nanotube could be great for electronics applications, but there’s new evidence that two could be tops.

One nanotube could be great for electronics applications, but there’s new evidence that two could be tops. bulk quantities of just about any carbon source into valuable graphene flakes. The process is quick and cheap; Tour said the “flash graphene” technique can convert a ton of coal, food waste or plastic into graphene for a fraction of the cost used by other bulk graphene-producing methods.

bulk quantities of just about any carbon source into valuable graphene flakes. The process is quick and cheap; Tour said the “flash graphene” technique can convert a ton of coal, food waste or plastic into graphene for a fraction of the cost used by other bulk graphene-producing methods.

When is a circle less stable than a jagged loop? Apparently when you’re talking about carbon nanotubes.

When is a circle less stable than a jagged loop? Apparently when you’re talking about carbon nanotubes.